Are Alumina PCBs Compatible

Alumina PCBs are ceramic circuit boards that support high-performance and reliability demands for extreme temperature or hostile environment electronics projects. They are highly thermally conductive and demonstrate superior insulation capabilities. These advantages make them the ideal choice for demanding power, electronic and industrial applications.

alumina pcb are able to dissipate localized heat quickly through the core and base plate sinks, helping keep components below maximum junction temperatures. The material’s electrical properties are also very stable across broad ranges of operating temperatures, allowing for dense circuitry layouts. These factors make alumina substrates an ideal option for high-voltage applications, such as power management, aerospace and oil drilling.

Compared to traditional FR-4 laminate, alumina substrate PCBs exhibit greater strength and thermal conductivity. The material is able to withstand higher processing temperatures and has improved thermal expansion characteristics. In addition, alumina is resistant to harsh chemicals and corrosive environments.

Are Alumina PCBs Compatible With Flexible Electronics?

Due to these benefits, alumina pcbs are often used in harsh environments such as aerospace, military and oil drilling. They are also more durable than standard copper boards and can withstand large amounts of voltage. Additionally, alumina substrates are less susceptible to moisture absorption than other materials such as FR-4. This helps avoid outgassing and vapor pressure stresses during operation.

Are alumina PCBs compatible with flexible electronics?

While the metallization and fabrication methods for alumina and standard FR-4 are similar, alumina PCBs offer unique properties that make them better suited for specialized high-reliability or harsh environment electronics. However, alumina PCBs are not compatible with flexible electronics, as they cannot flex or bend as a standard PCB.

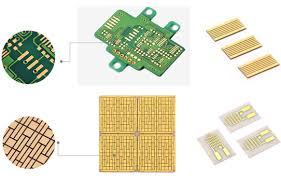

The alumina construction is typically comprised of three layers – a copper circuit layer around 1-20 oz thick, an insulating layer of thermally conductive and electrically insulated material, and a metallic base plate. The insulating layer of the alumina pcb can be made from several different materials including Aluminum Oxide (Al2O3). The insulating layer is hermetic, providing good resistance to abrasions and corrosion.

PCB manufacturers fabricate alumina substrates by applying metallized patterns to the surface of the sintered alumina base plates. These patterned areas are then etched to create pads, planes and traces, just like in a standard PCB. Conductors are then applied to the alumina circuit board with screen printing or thick film technology. Alumina can support a variety of conductor thicknesses, from 0.25mm to over 1.5mm.

These alumina pcbs can then be assembled with a wide range of components, such as semiconductors, resistors, switches and diodes. The final products are then subjected to rigorous electrical, thermal and mechanical tests to ensure the integrity of the finished circuits.

Properly fabricated alumina ceramics can provide extended working lifespans up to 50 years. Tight material and dimensional control throughout production minimizes flaws that can lead to latent shorts and opens, helping to achieve high mean time between failures. Moreover, alumina PCBs meet the purity requirements mandated by regulatory bodies for use in close human tissue proximity, such as in implantable medical devices.